Plastic has become a ubiquitous substance in contemporary life. The versatile qualities of plastics like easy to manage, resilient, glossy, more affordable and feasibility for mass production make it an ideal option.

Undeniably, plastic is gradually replacing the paper, metal, wood, glass, and other substances on the marketplace. For more information about polypropylene mesh read this article

Recently, plastics are used almost in every industry around the planet. In the water jar, soft drinks packaging into the durable car to plane accessories, everything could be made from plastic nowadays. Plastic is matchless in regards to consumer-friendly, cost-effective, sustainable and shiny products.

However, how can plastic get such varied characteristics and features?

The features of plastic are characterized by using the masterbatch and production process used at the plant. The varied color, durability, tensile strength, gloss, resistance to weather and heat are determined during the manufacturing process.

Masterbatch is a liquid and solid additive added to the plastic to provide color and improve features in the final product. The MB and additives are added to the carrier resin in various proportions based on the desired outcome on the plastics.

PP Woven Masterbatch

Polypropylene is a polymer utilized in the automotive, textile and food packaging enterprise. The PP is immune to the chemical solutions.

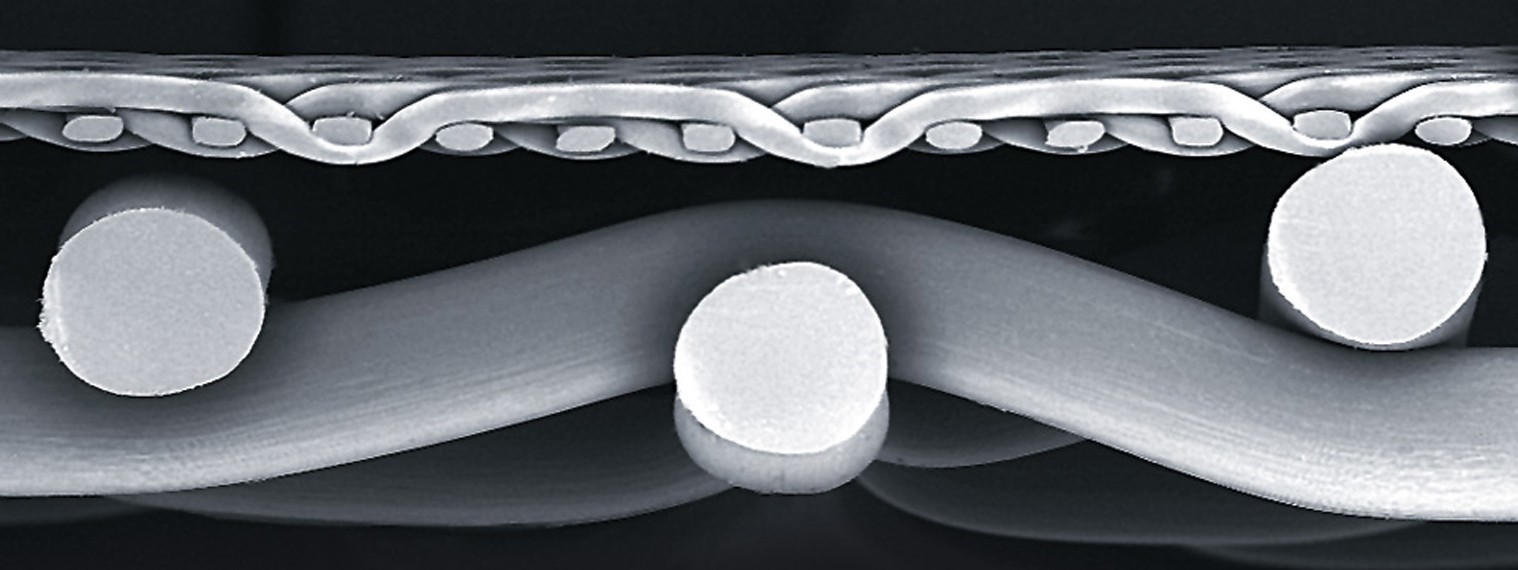

Woven sack extrusion

Using PP from the woven sack production is a standard used in transporting and storing food grains to compost. With the usage of PP woven masterbatch, the sacks gain attributes such as water-proof, tensile strength and durability required to be excellent packing materials.